Modern drive technology for automatic conveyor systems

Intralogistics & Conveyor Technology

Reliability, clocking, efficiency – when everything has to mesh smoothly.

Drive technology for intralogistics, warehousing and distribution processes: Precise, low-maintenance and compact drive technology is important in these processes. Whether it’s a conveyor line, picking area or automated storage system – our geared motors ensure that the flow of goods flows and processes run reliably. As a manufacturer with decades of experience, we supply both proven standard solutions and customer-specific drives that fit your conveyor technology exactly.

Typical areas of application

- Roller conveyors, belt conveyors, drag conveyors

- Vertical conveyors, lifter systems and vertical jacks

- Shuttle systems in small parts warehouses

- Sorting systems with diversion, lifting or rotating units

- Picking workstations with variable conveyor speed

- Packaging and shipping lines

- Intelligent conveyor systems

Geared motors for intralogistics & conveyor technology

01.

Suitable selection of worm gears

SN15

Nominal torques

2.6 – 4.7 Nm

Ratios

i= 3 – 110

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN18

Nominal torques

5.3 – 15 Nm

Ratios

i= 2.5 – 167

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN3

Nominal torques

11 – 17 Nm

Ratios

i= 5 – 75

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN6

Nominal torques

11 – 15 Nm

Ratios

i= 50 – 1520

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN9

Nominal torques

23 – 36 Nm

Ratios

i= 7 – 80

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN13

Nominal torques

31 – 70 Nm

Ratios

i= 15 – 591

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

02.

Perfectly tuned drive system:

Smart-Line

The intelligent solution.

Functions

For the intelligent, feature-rich frequency inverter with I/O interfaces and advanced functions.

Advantages

Our Smart-Line frequency converters are ideal for automated conveyor systems with variable speed, cycle operation or system-controlled load control. In combination with planetary or worm gears, a versatile, efficient drive is created.

- Parameterization via software or HMI

- Connection to sensors and controls (e.g. PLC)

- Interfaces such as Modbus, IO-Link, etc.

- Soft start, ramps, braking systems integrated

- Particularly suitable for automated storage and conveyor technology

Downloads

Easy-Line

The manual solution.

Functions

For the simple, user-friendly frequency inverter that can be quickly and easily used through manual control.

Advantages

If you want to be pragmatic and economical: The Easy-Line frequency converters are reduced to the essentials – simple commissioning, manual speed adjustment, robust technology. Perfect for standard conveyors with a clearly defined load profile.

- Speed control via potentiometer

- Quick installation, minimal parameterization

- Compact and low-maintenance

- Ideal for non-automated conveying solutions

Your advantages

Planetary gearboxes, worm gears and spur gears combined with modern converter technology

Whether pallet conveyors, roller conveyors or lift tables – in intralogistics, drives must be reliable, efficient and flexibly controllable. With our low-backlash planetary gearboxes (RPL/RPS) and robust worm gearboxes, we offer you proven solutions for a wide range of conveying tasks. In combination with our frequency converters, this becomes an all-round intelligent drive system – tailored to your requirements.

Benefits for your industry

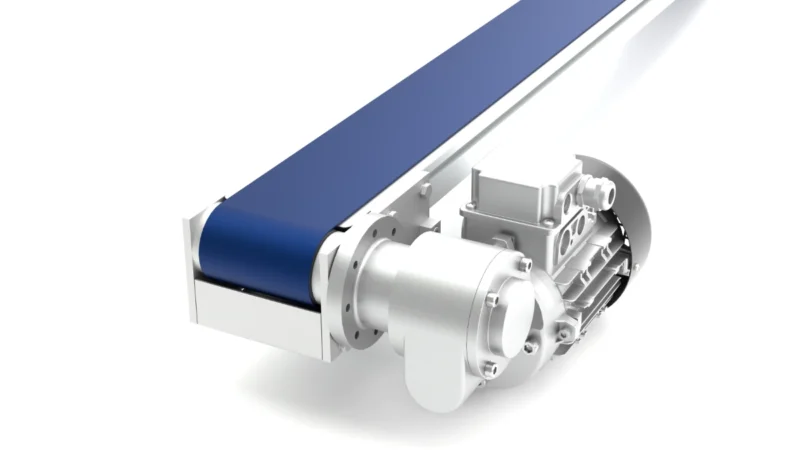

Advantages of worm gears in conveyor technology

Compact, robust and quiet – ideal for conveyor technology with limited installation space. Due to the high gear ratios, they are particularly suitable for light to medium loads.

- Compact, easy-to-install designs

- Endurance-resistant & low-maintenance – ideal for 24/7 operation

- Flexible connectors & flanges for easy integration

- Immediately available from stock – for standard configurations

- Intelligent control through inverter solutions (SmartLine / EasyLine)

- Individual adaptation possible: flange, shaft, tension, painting – depending on requirements

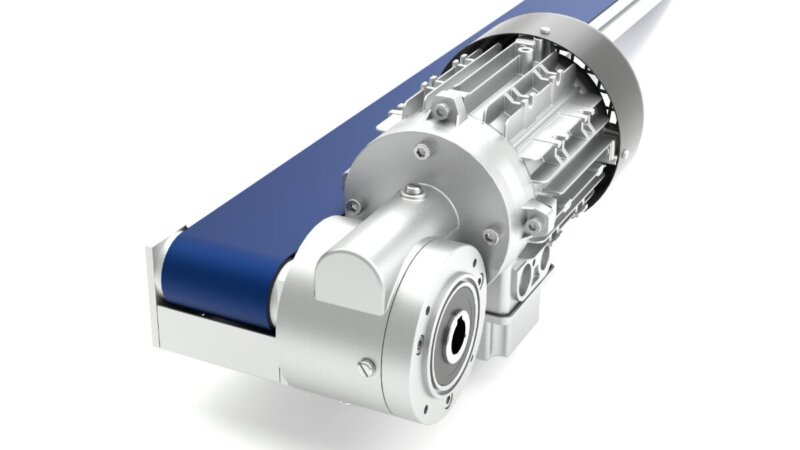

Advantages of cylindrical gears in conveyor technology

In multi-storey logistics centres, pallets and containers are transported to different levels via vertical conveyors. Our HG series helical gearboxes offer the necessary power and smoothness here – combined with a standard motor or intelligently controlled via the SmartLine.

- High power density

- Smooth, low-noise running

- Efficient efficiency

- Robust design for continuous operation

- Easy integration with IEC standard motors

- Versatile in use

- Optionally with intelligent control

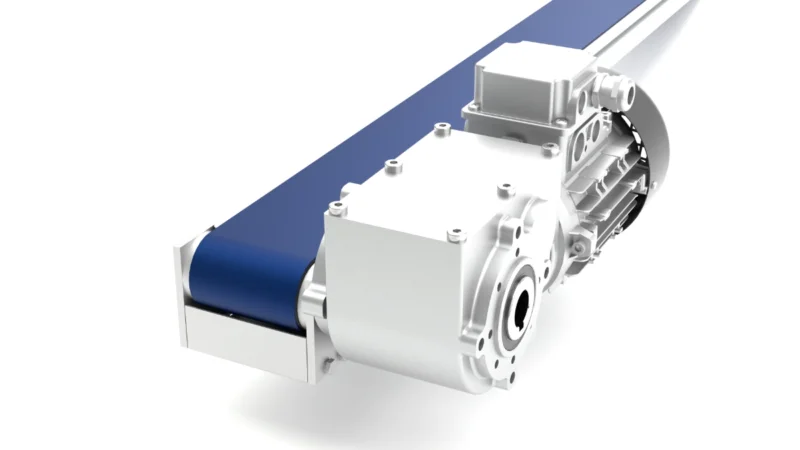

Advantages of planetary gearboxes in conveyor technology

Planetary gearboxes are ideal for applications in conveyor technology where compact design, high torque density and precise controllability are required. They are used wherever movements have to be implemented precisely, dynamically and in a space-saving manner – for example in shuttles, lifts or rotating modules.

- High power density in a compact design

- Backlash-free or low-backlash design for exact positioning

- High efficiency for energy-efficient continuous operation

- Stepless speed control in combination with frequency converter

- Low-maintenance and long-lasting operation even at high clocks

- Flexible installation options in horizontal, vertical or inclined position

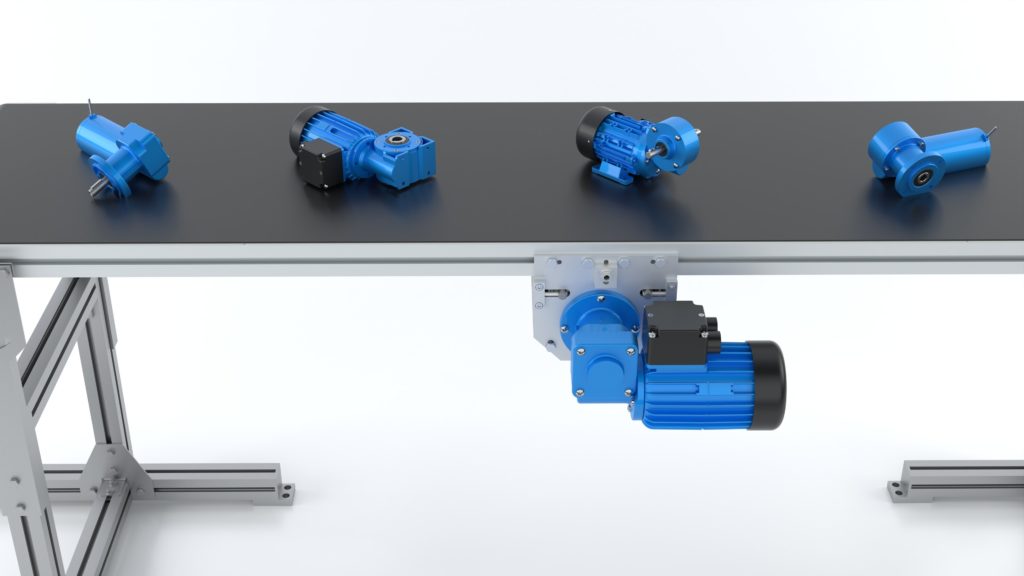

Experience the flexibility of our modular system

With our modular system, we offer flexible solutions that meet a wide range of requirements and industries. Thanks to modular components, gearboxes and motors can be individually combined to create customized drives for various applications.

Examples

Applications for worm gears in conveyor technology

Roller conveyors for general cargo transport

Worm gears drive conveyor rollers directly or via chains – ideal for light to medium loads in internal transport.

Belt conveyors for cartons and crates

Belt conveyors with a flat design use worm gears for space-saving power transmission – especially in shipping lines or packaging stations.

Diverters & Conveyor Belt Deflections

Deflection units and direction changers are driven by compact worm gears – often with lateral mounting directly under the belt.

Pusher / Slider for separation or sorting

Mechanical gate valves are driven by worm gears – e.g. for targeted transfer on branch lines.

Small conveyors in picking areas

Worm gear motors drive short conveyor lines, for example between the storage and retrieval machine and the packaging station.

- Belt curves

- Roll curves

- Modular belt conveyors

- Link belt conveyor

- Wire Belt Conveyor

- Chain conveyor

- Belt conveyors

- Rotary tables

- Vertical conveyors

- Lifting devices

- Handling systems

- Pallet conveyors

- Picking systems

Applications for helical gearboxes in conveyor technology

Vertical conveyors / vertical conveyors

Spur gears drive lifting platforms or lifts that transport containers or pallets between multiple levels.

Pallet conveyor systems

Drive of chain or roller conveyors in the field of pallet logistics – often with higher weight and greater drive requirements.

Lifting/lowering mechanisms at transfer stations

For example, for lifting roller conveyors, moving load carriers or controlling pneumatic elements via cranks.

Conveyor systems with deflection stations or branches

Where, for example, rollers are driven by chain hoists or carriers that run over a central axis.

Conveyor systems with deflection stations or branches

Guide units or stoppers can be moved precisely and synchronously via spur gear drives.

Rotary tables & rotary modules in conveyor systems

Spur gears drive rotating units that rotate transported goods by 90°, 180° or 360° – for example, at transfer stations, pallet changers or switches.

Applications for planetary gearboxes in conveyor technology

Shuttle vehicles in small parts warehouses

Planetary gears drive the traversing axes or lifting mechanics in shuttle systems – compact, lightweight and precise.

Compact planetary gearboxes for pick-and-place units

Positioned lifting movements in automated storage systems, e.g. at lift modules or transfer points.

Conveyor belt axles with change of direction

Loading and unloading of load carriers via intermittent conveyor belts with exact positioning.

Load Transfer Rotary Tables

Planetary gearboxes move rotating conveyor platforms that convey goods through 90° or 180°.

Adjustable guide and stop elements

Movable side elements or mechanical stoppers in intelligent conveyor lines.

Lifting modules with compact design

Compact lifting devices, e.g. in picking areas or intermediate stations, require backlash-free, powerful drives.