Drive solutions for modern material flows

Mechanical Engineering & Special Equipment

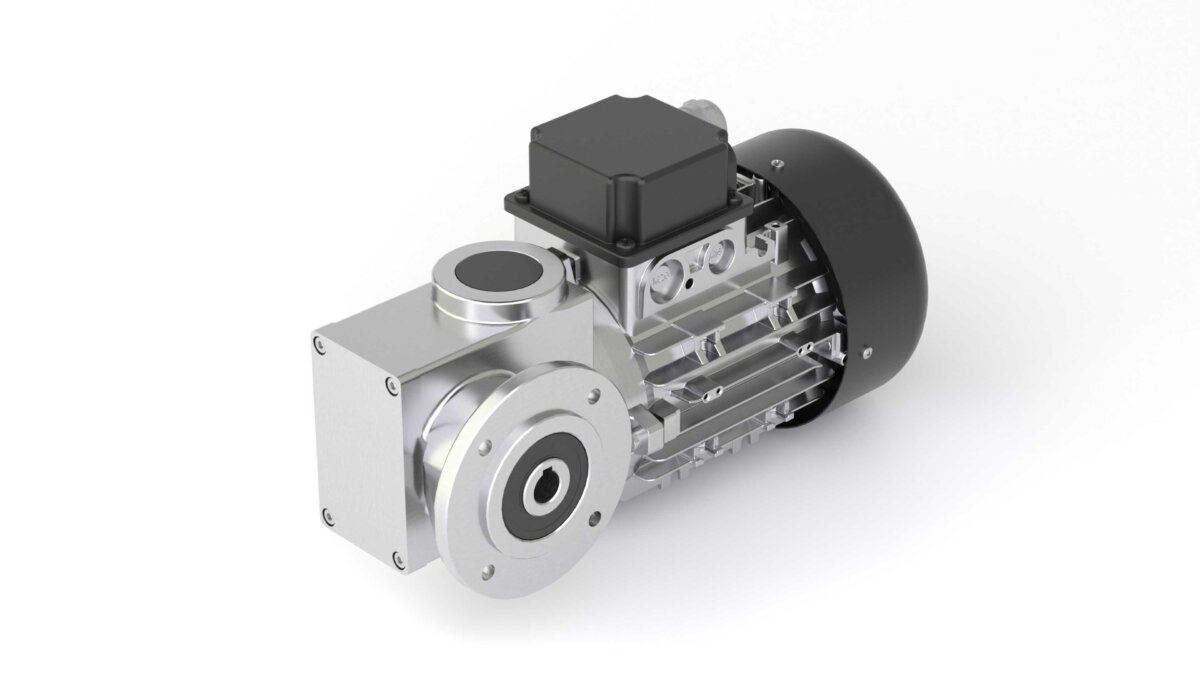

Drive technology for individual machine solutions – flexible, reliable, tailor-made

Whether it’s a series machine or a special design – with us you get more than just a gearbox or geared motor.

In mechanical engineering and special plant engineering, flexibility, variety of variants and precise integration are crucial. Ruhrgetriebe supplies compact geared motors that are individually tailored to performance, installation situation and control – from modular standard solutions to specially developed special gearboxes from small series numbers.

Typical areas of application

- Conveying, packaging or assembly systems

- Inspection and test systems

- Tool changers and handling modules

- Turntables, rotary tables and linear actuators

- Machines in confined or dynamically stressed installation spaces

- Machines for the environment, laboratory, energy or lightweight construction

Geared motors for mechanical engineering & special systems

Choice of worm gears

SN6

Nominal torques

11 – 15 Nm

Ratios

i= 25 – 1520

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN8

Nominal torques

54 – 113 Nm

Ratios

i= 5 – 75

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN19

Nominal torques

139- 150 Nm

Ratios

i= 33 – 394

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

SN15

Nominal torques

2 – 4 Nm

Ratios

i= 3 – 110

Output shaft

Hollow Shaft, Solid Shaft

Data Sheets

Choice of planetary gearboxes

RPS series

Nominal torques

14 – 92 Nm

Ratios

i= 3 – 512

Diameter

40, 60, 80 mm

Data Sheets

RPL series

Nominal torques

7 – 60 Nm

Ratios

i= 3 – 100

Diameter

50, 70, 90 mm

Data Sheets

Selection of helical gearboxes

HG141

Nominal torques

15 – 30 Nm

Ratios

i= 1.29 – 8.17

Motor type

IEC electric motor

Data Sheets

HG281

Nominal torques

40 – 108 Nm

Ratios

i= 1.14 – 7.36

Motor type

IEC electric motor

Data Sheets

HG252A

Nominal torques

96 – 206 Nm

Ratios

i= 3.70 – 67.47

Motor type

IEC electric motor

Data Sheets

HG303A

Nominal torques

320 – 380 Nm

Ratios

i= 64.91 – 372.35

Motor type

IEC electric motor

Data Sheets

Benefits for your industry

Advantages of worm gears in mechanical engineering

Worm gearboxes are particularly suitable for compact machine designs where space constraints, quiet running and holding function are required. They offer right-angled power transmission and allow flexible mounting.

- Compact design for tight installation spaces

- Integrated self-locking prevents unwanted trailing

- Low-noise and vibration-free operation

- High gear ratios can be achieved in a single stage

- Freely selectable installation position for flexible constructions

- Maintenance-free operation due to permanent lubrication

Advantages of cylindrical gearboxes in mechanical engineering

Helical gearboxes are robust, efficient and ideal for drives with continuous loads. They are particularly suitable for lifting systems, chain conveyors or feed modules with constant load behaviour.

- High efficiency for energy-efficient continuous operation

- Constant and uniform power transmission

- Robust design for industrial applications

- Compatible with IEC standard motors for easy integration

- Thermally resilient for continuous operation applications

- Available in numerous sizes and gear ratios

Advantages of planetary gearboxes in mechanical engineering

Planetary gearboxes offer high precision, high torque density and are ideally suited for dynamic movements. They are often used in rotary tables, grippers or cycle axes.

- Very high power density with compact dimensions

- Backlash-free or low-backlash versions for exact positioning

- High efficiency in multi-stage variants

- Perfectly suited for dynamic motion profiles

- Durable, low-maintenance construction

- Can be used for applications with the highest requirements for accuracy and compactness

Experience the flexibility of our modular system

With our modular system, we offer flexible solutions that meet a wide range of requirements and industries. Thanks to modular components, gearboxes and motors can be individually combined to create customized drives for various applications.

Application Examples

Applications for worm gears in mechanical engineering

Worm gears for compact swivel modules in special machines

Quiet, space-saving drives for swivel units and holding functions – ideal for confined installation spaces.

Worm gears as stopper drives in conveyor systems

Self-locking and reliable: For the safe stopping and separation of workpiece carriers.

Worm gears for belt diverters & conveyor drops

90° power transmission with minimal space requirement – perfect for branching in transport lines.

Variable speed drives with worm gears for machine axes

Robust drive solution for sporadically adjusted modules and positioning units.

Clamping units & clamping devices with worm gears

Secure holding function thanks to high reduction ratio – maintenance-free and durable.

Swivel arms in assembly stations with compact worm drive

For ergonomically movable workstations – powerful and quiet.

Applications for helical gearboxes in mechanical engineering

Spur gears for lifting systems & linear movements

Reliable feed drive for lifting tables, spindle axes and linear assemblies.

Spur gears as drive for chain conveyors

High load capacity with smooth running – ideal for workpiece transport and pallet conveying.

Cross conveyor units with robust spur gear drive

Movement of load platforms or workpiece carriers in transverse axes.

Press feed drives with spur gears

Spur gears ensure uniform pressure feed in assembly or embossing units.

Tilting modules with helical gears

For constant, powerful tilting movements in the machine process – e.g. for turning components.

Continuous shaft drives with spur gears

Two-sided power transmission for synchronized movements – e.g. in clamping systems.

Applications for planetary gearboxes in mechanical engineering

Planetary gearboxes for rotary tables and cycle modules

Exact positioning in dynamic motion – for assembly and testing applications.

Compact planetary gearboxes for pick-and-place units

Ideal for gripping axes and handling modules with limited space and high precision.

Tool changer with backlash-free planetary gears

Reliable movements for tool rotations and automatic tool change systems.

Planetary gearboxes for linear drives with timing belts or spindle

Powerful solution for CNC axes, machining gantries and inspection modules.

Dynamic planetary drive turning units

Fast, precisely repeatable 180° rotation for machine processes and test stations.

Continuous shaft drives with spur gears

Backlash-free return to zero position – precise and maintenance-free.