Spur Gear Motors & Spur Gears

- Gear Type

Spur gear

- Series

11 gear series, 1,219 variants

- Nominal torques

15 – 380 Nm

- Mounting

Gear Flange, Gear Foot, Motor Foot

- Mounting Dimensions

IEC Standard Flange

- Electric motors

All common IEC electric motor types

- Sizes

BG56 – BG90

Experience our versatile industrial gear motors.

Delivery time

Within a few working days

Flexibility

Connect motor types from any manufacturer without any problems!

Spur Gear Motors: Versatile and Efficient Solutions for Industrial Applications

Helical geared motors are a versatile and efficient solution for various industrial applications requiring high torque. With a power range of 15 - 380 Nm, these motors offer a wide range of power options to meet the needs of different industries.

- Short delivery times

- 11 Standardreihen11 Standard series

- Torque range from 15 to 380 Nm

- Motor mounting according to IEC standard

- Various designs available

- Modular modules allow individual customizing

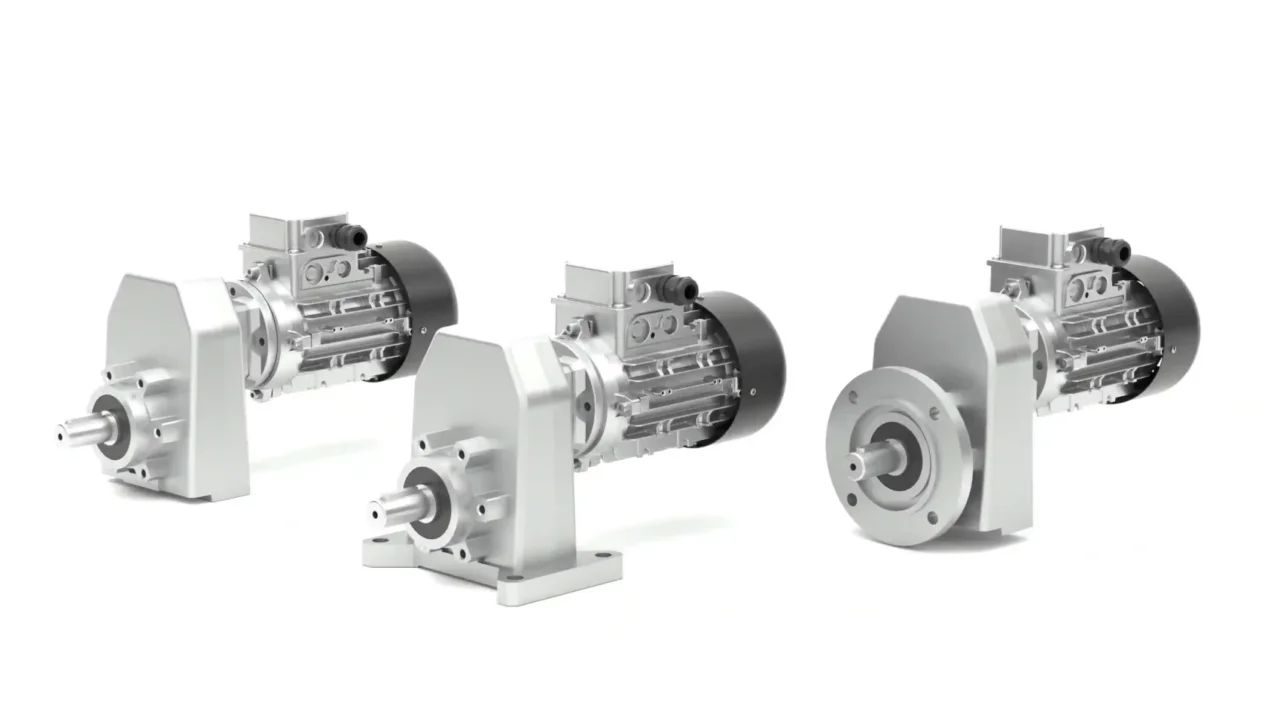

Mounting Versions of Our Helical Gear Units

Type P

Gearbox with foot

Nominal torques

15 – 380 Nm

Ratios

i= 1.14 – 372.35

Motor attachment

IEC standard

Type NF

Gearbox with flange

Nominal torques

15 – 380 Nm

Ratios

i= 1.14 – 372.35

Motor attachment

IEC standard

Type N

Motor with foot

Nominal torques

15 – 380 Nm

Ratios

i= 1.14 – 372.35

Motor attachment

IEC standard

Key Features of Spur Gear Motors

High efficiency

Helical geared motors have high mechanical efficiency as they have less internal friction compared to other types of gearboxes. This leads to an efficient conversion of electrical energy into mechanical power.

High torque density

Helical geared motors offer high torque density, meaning they can deliver high torque relative to their size and weight. This makes them ideal for applications that require high torque, such as conveyors, cranes, machine tools, etc.

Precise and reliable power transmission

Due to their design, helical geared motors offer precise and reliable power transmission. The gears in the gearbox ensure accurate torque transmission and minimise backlash, resulting in precise positioning and reliable performance.

Low Noise

In general, helical geared motors produce relatively little noise compared to other types of gearboxes. This is due to the good contact design of the gears and the high rigidity of the gear assembly.

Versatile in use

Helical geared motors are used in a wide range of applications, including mechanical engineering, automation technology, materials handling, robotics, packaging machines, CNC machines, machine tools, medical technology and many other areas.

Low-maintenance due to permanent lubrication

Thanks to their closed design and lifelong grease filling, they are particularly easy to maintain and durable in operation.

Can be combined with different engine types

Whether standard motor, EC motor or integrated converter (e.g. SmartLine) – our worm gears have a modular design and can be flexibly combined.

Variety of variants & special solutions

Thanks to our vertical range of manufacture, individual adaptations in flange, shaft, colour or transmission are possible – even from small quantities.