Find the right gear motor

Product overview

In perfect balance: Gearbox and electric motor for dynamic performance.

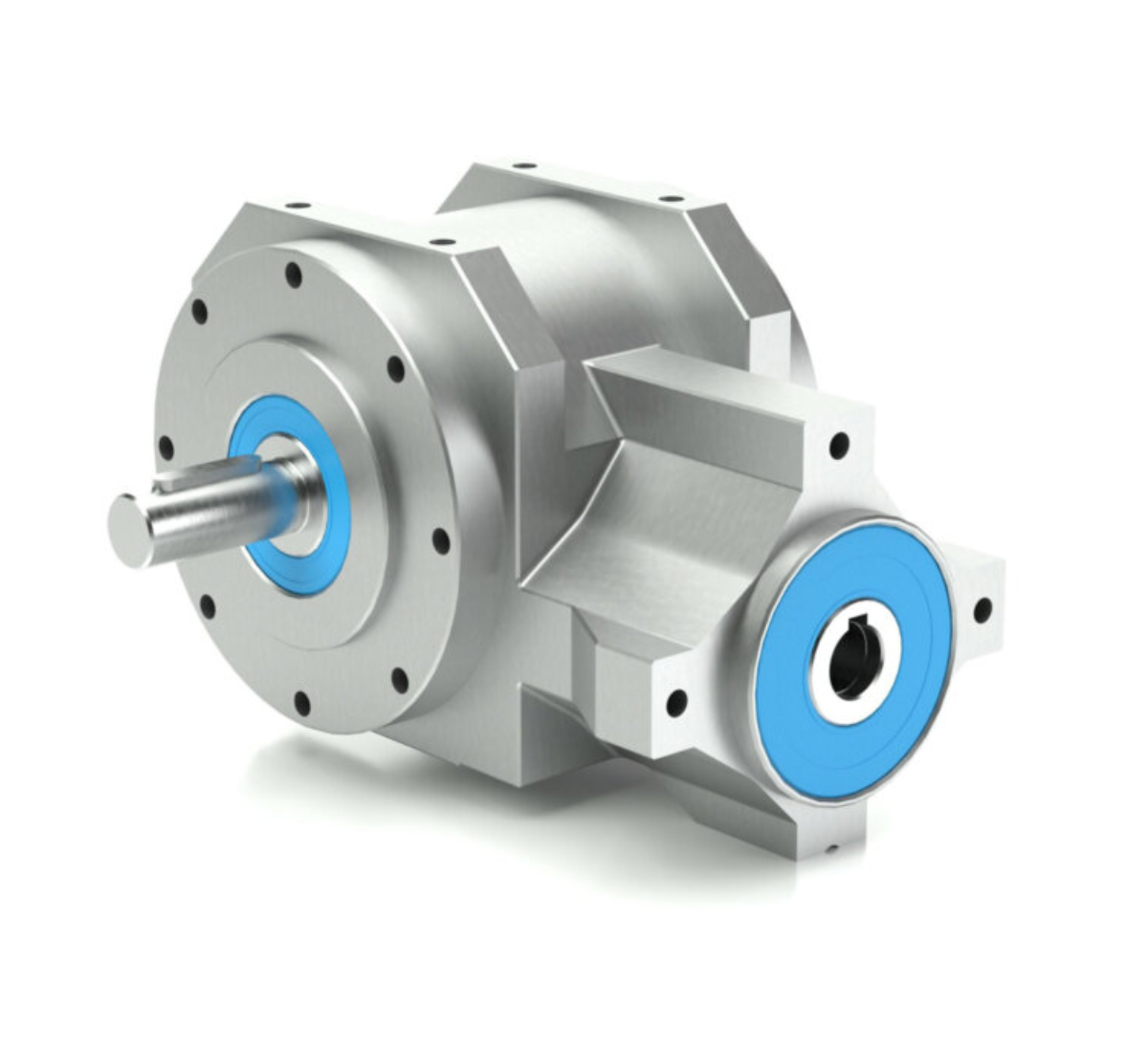

Ruhrgetriebe gearboxes

The right geared motor for every application

Ruhrgetriebe represents innovative gear motor solutions that are compact, versatile, and perfectly tailored to the demands of modern drive technology. As an experienced manufacturer, we develop drives that integrate seamlessly into any production process – precise, powerful, and reliable. Our gear motors deliver maximum flexibility and efficiency while focusing on standardized and future-proof solutions.

Our modular system for gear motors is flexibly tailored to the diverse requirements of your application areas.

The perfect match:

Gearbox & electric motor

1. Our gears provide movement.

Worm Gearboxes

Nominal torques

2 – 288 Nm

Ratios

i= 2.5 – 8000

Output shaft

Hollow Shaft, Solid Shaft

Motor attachment

Special dimensions

Planetary Gearboxes

Nominal torques

7 – 92 Nm

Ratios

i= 24 – 512

Output shaft

Solid shaft

Motor attachment

IEC standard

Spur gear

Nominal torques

15- 380 Nm

Ratios

i= 1.14 – 372.35

Output shaft

Solid shaft

Motor attachment

IEC standard

SpeeroXgearbox

Nominal torques

25 Nm

Ratios

i= 15 / 24 / 55

Output shaft

Solid shaft

Motor attachment

IEC standard

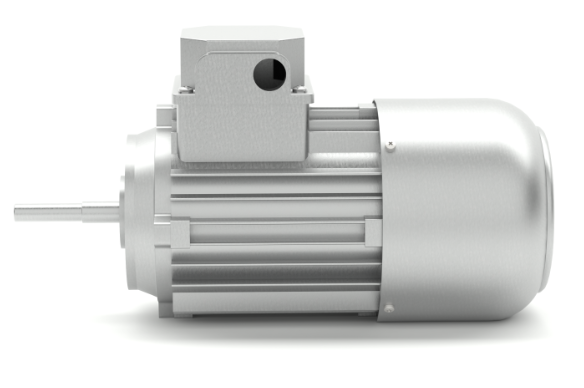

2. The right electric motor makes them perfect.

Three-phase asynchronous motors

Power

0,032 – 1,50 kW

Voltages

230/400 V | 277/480 V

Protection types

IP54 – IP65

Designs

B3 / B14

Versions

Custom-made / IEC standard

Brushed & Brushless DC motors

Power

0,028 – 0,093 kW

Voltages

24 V

Protection types

IP40 – IP55

Designs

B3 / B14

Versions

Customized

DC shunt wound motors

Power

0,12 – 0,55 kW

Voltages

180 / 200 V

Protection types

IP44 – IP55

Designs

B3 / B14

Versions

Customized

Single-phase asynchronous motors

Power

0,032 – 1,10 kW

Voltages

230 V

Protection types

IP54 – IP55

Designs

B3 / B14

Versions

Customized + IEC standard

Can't find a suitable solution?

At Ruhrgetriebe, we develop customized gearbox solutions precisely tailored to your requirements. With innovative technology, high in-house production depth, and decades of experience, we create drive units that are not only reliable but also future-proof.

Available options for your configuration

Customize your selected geared motor to meet your exact requirements. In addition to the standard version, we offer you numerous options to configure your geared motor individually.

Lubrications

Choosing the right lubrication guarantees long service life and reliable performance. Different options are available depending on the environment and application.

- Standard lubrication for standard operating conditions

- High-temperature lubricant for demanding thermal applications

- Food-safe lubrication (NSF H1) for use in hygienic environments

- Low-temperature lubrication for cold-area applications

Output shaft

The output shaft can be customized to fit your machine. Various designs provide an optimal mechanical connection.

- Standard output shaft with key

- Special length according to customer specifications

- Hollow shaft for compact installation

- Stainless steel output shaft for corrosive environments

Paint finish

Our worm gear motors come in the standard color RAL 9006 (white aluminum). Other colors and special coatings are available upon request.

- Standard paint RAL 9006 (white aluminum)

- Additional RAL colors upon request

- Custom coatings on request

- Hygienic paint for food industry applications

Surface coating

We offer additional protective measures and coatings for use in harsh or hygienically sensitive environments. They enhance the service life and reliability of your drive system.

- Corrosion protection for damp or salty environments

- Hygienic surface coating for the food industry

- Chemical-resistant paint for harsh environments

- Enhanced sealing for higher IP protection

Operating mode

Our geared motors can be operated with different control concepts, allowing you to maintain full control over speed and torque.

- Operation with mounted frequency inverter

- SmartLine for precise and dynamic regulation

- EasyLine for easy manual operation

- Mains operation without inverter for standard applications

Additional functions

Expand your drive system with additional components to enhance safety, functionality, and monitoring.

- Electromagnetic motor brake

- Extra shaft sealing

- Temperature or rotational speed sensor